- Home

- Sustainability Management

- Supply Chain Management

Creating Sustainable Value Chain

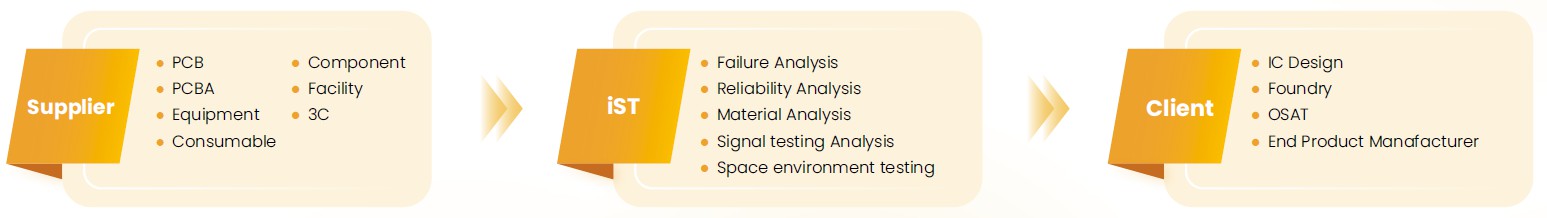

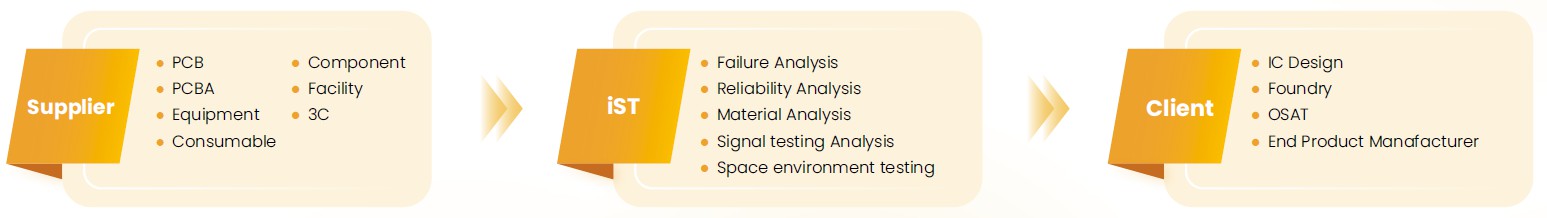

iST Value Chain

iST regards its suppliers as partners in creating shared value, aspiring to work together to build a sustainable service value chain. While delivering the best solutions to customers, we also strive to reduce environmental and social risks, thereby establishing a proactive and responsible value chain network."

Policy and Target

To establish supplier management systems and specifications, comply with quality/cost/delivery/service/technology and ESG management systems, and require upstream supply chain management and supplier corporate social responsibility fulfillment commitments.

Supply Chain

iST, a laboratory for verification and analysis of electronic industry. In order to ensure the provision of professional and timely service quality to important international customers, we have specially formulated supplier management procedures and procurement management procedures to classify suppliers. Grade I-PCB and assembly sites with transaction volume exceeding 5,000,000NTD per year. Grade II-A-Taiwanese PCB and BGA processing sites with transaction volume under 5,000,000 NTD per year. Grade II-B-Socket distributors and overseas PCB sites. Grade III-Facility construction, repair/maintenance service Suppliers, test subcontractors. Grade IV-Equipment suppliers and others、Grade IIV-Chemical suppliers. And perform hierarchical management according to the attributes and importance of suppliers at each level.

Supplier Management

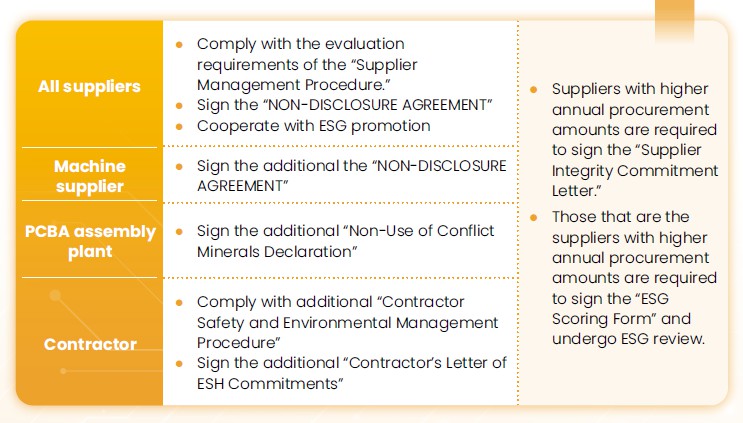

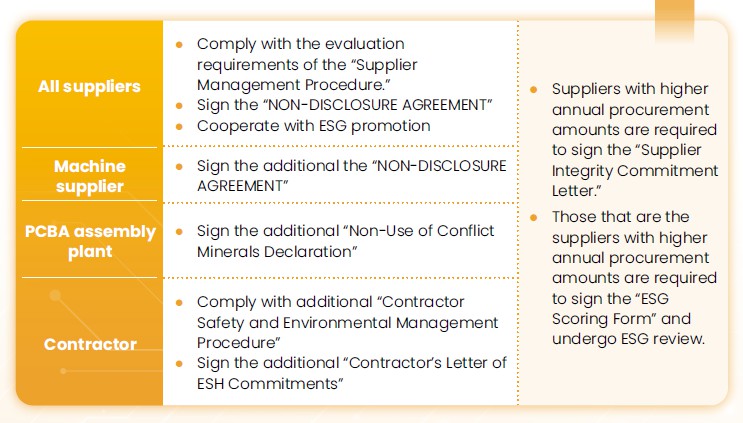

iST upholds the principles of sustainable development, environmentally friendly, ethical management, and information security. iST and suppliers collaborate on environmental, security, health, and other issues to fulfill corporate responsibilities. The“iST Supplier Code of Conduct” is published on the official website, serving as a standard for supplier adherence. A summary is provided below:

ESG Management and Annual Audit

To ensure product quality and on-time delivery meet Company and customer requirements, iST has established “Suppliers Management Procedure” and “Purchasing Management Procedure.” iST assesses and evaluates critical suppliers based on quality policies, management processes, supply chain management, and anomaly management. A score above 70 is qualified, 60-70 is conditionally approved, and below 60 is not approved. Qualified suppliers are required to sign a “NON-DISCLOSURE AGREEMENT” to safeguard sensitive information.

iST conducts annual evaluations for key suppliers engaged in significant transactions. The evaluation is based on criteria such as cost, delivery, service, and process. Scores above 3.5 are considered qualified, scores between 3.0 and 3.5 are conditionally approved, and scores below 3.0 are considered not qualified. In 2023, an ESG evaluation for supplier sustainability was added to the annual evaluation scoring items, including an ESG self-assessment survey. In 2024, 55 suppliers were evaluated, all of whom were qualified and had no severe ESG violations. We will continue to optimize supplier ESG evaluation standards and implement audit and guidance mechanisms.

iST also conducts both regular and random on-site assessments of suppliers. These assessments encompass an evaluation of the supplier’s process capabilities, quality standards, delivery control, and internal management processes. Since the 2023 assessment, corporate social responsibility has been added as a criterion, reviewing suppliers’ adherence to occupational safety, environmental protection, and labor rights. In cases where discrepancies are identified, the supplier is required to implement improvement measures continuously, reduce procurement volumes, or terminate the business cooperation in severe cases. In 2024, the Company conducted on-site visits to suppliers of key assembly plants. The visit results confirmed compliance with iST’s Supplier Code of Conduct regarding labor rights, ethical business practices, information security, health and safety, and environmental protection.

iST mandates that all construction contractors and equipment suppliers entering our premises undergo safety induction training provided by our Environmental Health and Safety (EHS) unit. In 2024, 15 safety education sessions were held with 132 participants. Waste disposal contractors must possess relevant certifications and comply with environmental regulations, signing a “Contractor’s Letter of ESH Commitments” to ensure adherence to safety and environmental management guidelines.

iST requires suppliers to commit to strict adherence to the Company’s established integrity-related regulations. During the course of normal business transactions with iST, suppliers are obligated to refrain from engaging in any bribery, offering inducements, or providing undue benefits to iST employees or their associates in order to facilitate business interactions. Suppliers are strictly prohibited from influencing, persuading, or enticing iST employees to deviate from their duties or faithful obligations to the Company. For suppliers involved in substantial financial transactions, the company mandates the signing of a “Supplier Integrity Commitment Letter.” In 2024, the 15 new commitment letters were issued to eligible suppliers, and all have successfully signed and returned the document.

In summary, when implementing our supply chain management, iST considers not only efficiency and costs, but also focuses on the performance of partners in various dimensions such as environment, society, and governance. Through regular evaluations, iST continuously understands the supplier operational status to enhance mutual sustainability, as well as encouraging the suppliers to internalize ESG into their company management and operations. This will enhance the overall resilience and adaptability of iST’s supply chain in facing unforeseen events, ensuring iST can consistently provide professional services to customers and maintain supply chain resilience.

ESG Green Procurement Policy

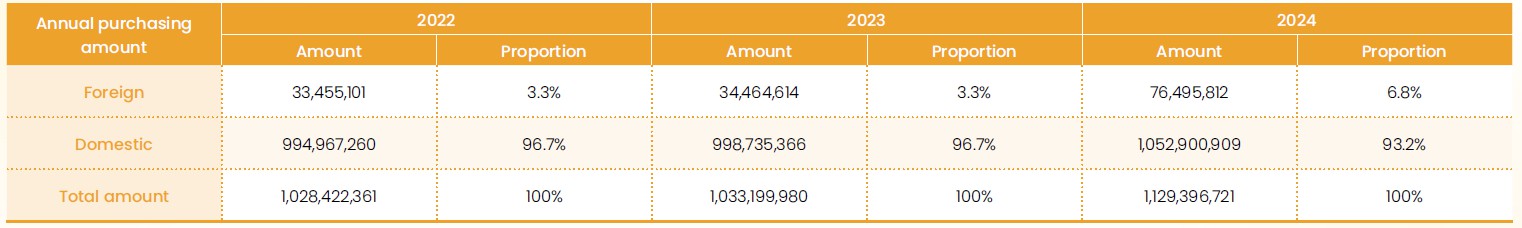

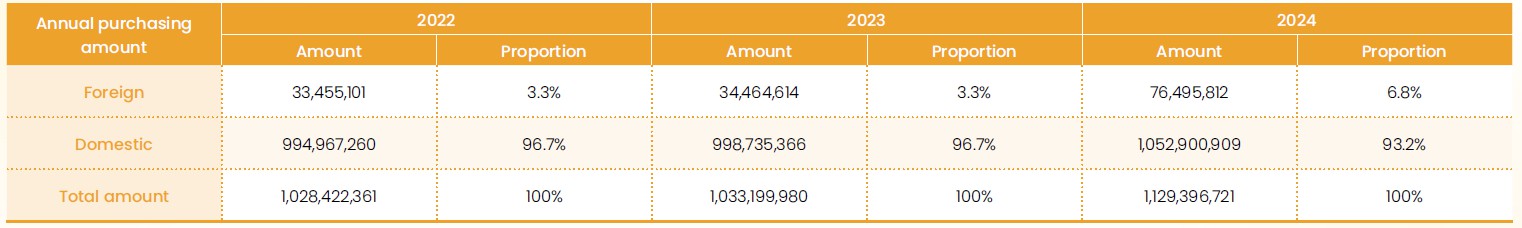

As a major third-party laboratory recognized by important domestic and international clients, iST’s equipment purchases are required to meet customer verification requirements. In addition to large equipment sourced from internationally renowned manufacturers, other items such as consumables, instruments, chemicals, outsourcing, and testing peripherals are purchased with the goal of sustainable operations. Considering energy-saving and environmental factors in procurement, logistics, recycling, and reuse processes. Collaboration with suppliers fulfills social responsibilities in environmental protection, energy conservation and emission reduction. Products are prioritized from local, environmentally friendly suppliers (with eco-labels and approved by the Ministry of Environment to be compliant with recycled materials) for creating a green supply chain. To enhance supply chain resilience, we developed 53 domestic manufacturers in 2024 to ensure supply continuity and optimize operational costs. iST also requires all suppliers to confirm ESG issues when accepting orders. Over the past three years, the proportion of domestic purchases, excluding large equipment, has consistently exceeded 90% (as detailed in the table below).

Conflict Minerals Sourcing Policy

Following OECD’s “Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas,” iST establishes a framework for responsible investigation. In addition to advocating the prohibition of “conflict minerals,” suppliers must sign the “Conflict Minerals Non-Usage Commitment” and provide supporting information in the annual supplier ESG survey to facilitate the evaluation of whether the raw materials and components provided by suppliers are conflict minerals. In 2024, investigations of seven new board and assembly factories confirmed their compliance with the “Conflict Minerals Non-Usage Commitment.” All suppliers have signed the “Conflict Minerals Non-Usage Commitment” with a completion rate of 100%.

Creating Sustainable Value Chain

iST Value Chain

iST regards its suppliers as partners in creating shared value, aspiring to work together to build a sustainable service value chain. While delivering the best solutions to customers, we also strive to reduce environmental and social risks, thereby establishing a proactive and responsible value chain network."

Policy and Target

To establish supplier management systems and specifications, comply with quality/cost/delivery/service/technology and ESG management systems, and require upstream supply chain management and supplier corporate social responsibility fulfillment commitments.

Supply Chain

iST, a laboratory for verification and analysis of electronic industry. In order to ensure the provision of professional and timely service quality to important international customers, we have specially formulated supplier management procedures and procurement management procedures to classify suppliers. Grade I-PCB and assembly sites with transaction volume exceeding 5,000,000NTD per year. Grade II-A-Taiwanese PCB and BGA processing sites with transaction volume under 5,000,000 NTD per year. Grade II-B-Socket distributors and overseas PCB sites. Grade III-Facility construction, repair/maintenance service Suppliers, test subcontractors. Grade IV-Equipment suppliers and others、Grade IIV-Chemical suppliers. And perform hierarchical management according to the attributes and importance of suppliers at each level.

Supplier Management

iST upholds the principles of sustainable development, environmentally friendly, ethical management, and information security. iST and suppliers collaborate on environmental, security, health, and other issues to fulfill corporate responsibilities. The“iST Supplier Code of Conduct” is published on the official website, serving as a standard for supplier adherence. A summary is provided below:

ESG Management and Annual Audit

To ensure product quality and on-time delivery meet Company and customer requirements, iST has established “Suppliers Management Procedure” and “Purchasing Management Procedure.” iST assesses and evaluates critical suppliers based on quality policies, management processes, supply chain management, and anomaly management. A score above 70 is qualified, 60-70 is conditionally approved, and below 60 is not approved. Qualified suppliers are required to sign a “NON-DISCLOSURE AGREEMENT” to safeguard sensitive information.

iST conducts annual evaluations for key suppliers engaged in significant transactions. The evaluation is based on criteria such as cost, delivery, service, and process. Scores above 3.5 are considered qualified, scores between 3.0 and 3.5 are conditionally approved, and scores below 3.0 are considered not qualified. In 2023, an ESG evaluation for supplier sustainability was added to the annual evaluation scoring items, including an ESG self-assessment survey. In 2024, 55 suppliers were evaluated, all of whom were qualified and had no severe ESG violations. We will continue to optimize supplier ESG evaluation standards and implement audit and guidance mechanisms.

iST also conducts both regular and random on-site assessments of suppliers. These assessments encompass an evaluation of the supplier’s process capabilities, quality standards, delivery control, and internal management processes. Since the 2023 assessment, corporate social responsibility has been added as a criterion, reviewing suppliers’ adherence to occupational safety, environmental protection, and labor rights. In cases where discrepancies are identified, the supplier is required to implement improvement measures continuously, reduce procurement volumes, or terminate the business cooperation in severe cases. In 2024, the Company conducted on-site visits to suppliers of key assembly plants. The visit results confirmed compliance with iST’s Supplier Code of Conduct regarding labor rights, ethical business practices, information security, health and safety, and environmental protection.

iST mandates that all construction contractors and equipment suppliers entering our premises undergo safety induction training provided by our Environmental Health and Safety (EHS) unit. In 2024, 15 safety education sessions were held with 132 participants. Waste disposal contractors must possess relevant certifications and comply with environmental regulations, signing a “Contractor’s Letter of ESH Commitments” to ensure adherence to safety and environmental management guidelines.

iST requires suppliers to commit to strict adherence to the Company’s established integrity-related regulations. During the course of normal business transactions with iST, suppliers are obligated to refrain from engaging in any bribery, offering inducements, or providing undue benefits to iST employees or their associates in order to facilitate business interactions. Suppliers are strictly prohibited from influencing, persuading, or enticing iST employees to deviate from their duties or faithful obligations to the Company. For suppliers involved in substantial financial transactions, the company mandates the signing of a “Supplier Integrity Commitment Letter.” In 2024, the 15 new commitment letters were issued to eligible suppliers, and all have successfully signed and returned the document.

In summary, when implementing our supply chain management, iST considers not only efficiency and costs, but also focuses on the performance of partners in various dimensions such as environment, society, and governance. Through regular evaluations, iST continuously understands the supplier operational status to enhance mutual sustainability, as well as encouraging the suppliers to internalize ESG into their company management and operations. This will enhance the overall resilience and adaptability of iST’s supply chain in facing unforeseen events, ensuring iST can consistently provide professional services to customers and maintain supply chain resilience.

ESG Green Procurement Policy

As a major third-party laboratory recognized by important domestic and international clients, iST’s equipment purchases are required to meet customer verification requirements. In addition to large equipment sourced from internationally renowned manufacturers, other items such as consumables, instruments, chemicals, outsourcing, and testing peripherals are purchased with the goal of sustainable operations. Considering energy-saving and environmental factors in procurement, logistics, recycling, and reuse processes. Collaboration with suppliers fulfills social responsibilities in environmental protection, energy conservation and emission reduction. Products are prioritized from local, environmentally friendly suppliers (with eco-labels and approved by the Ministry of Environment to be compliant with recycled materials) for creating a green supply chain. To enhance supply chain resilience, we developed 53 domestic manufacturers in 2024 to ensure supply continuity and optimize operational costs. iST also requires all suppliers to confirm ESG issues when accepting orders. Over the past three years, the proportion of domestic purchases, excluding large equipment, has consistently exceeded 90% (as detailed in the table below).

Conflict Minerals Sourcing Policy

Following OECD’s “Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas,” iST establishes a framework for responsible investigation. In addition to advocating the prohibition of “conflict minerals,” suppliers must sign the “Conflict Minerals Non-Usage Commitment” and provide supporting information in the annual supplier ESG survey to facilitate the evaluation of whether the raw materials and components provided by suppliers are conflict minerals. In 2024, investigations of seven new board and assembly factories confirmed their compliance with the “Conflict Minerals Non-Usage Commitment.” All suppliers have signed the “Conflict Minerals Non-Usage Commitment” with a completion rate of 100%.