- Home

- Environmental Sustainability Force

- Greenhouse Gas and Energy Management

Greenhouse Gas Management

Facing the challenge brought about by global climate change, we know very well that companies must reduce the GHG emissions generated from the operating process and thus mitigate the negative impact on the climate. In 2022, we were dedicated to promoting the awareness of green production and low carbon to facilitate premium ecological environment, fulfill our corporate social responsibilities, and put the corporate philosophy of sustainable operations into practice.

The Company established a greenhouse gas inventory management process in accordance with ISO 14064-1 and the greenhouse gas verification guidelines of the Ministry of Environment in 2021. In the same year, we conducted a self-inspection of greenhouse gas emissions at the Hsinchu Plant I. In 2022, the scope of the self-inspection was expanded to cover the entire plant. In 2023, the inventory results were verified by a third-party verification company, ensuring a complete understanding of the current greenhouse gas usage.

The GHG inventory of the Company is conducted with operational control as the boundary of the inventory organization. The plants participating in the inventory in 2024 are Hsinchu Plant I, Hsinchu Plant II, Puding Plant, Dean Plant, Taiyuan Plant, Changyi Plant, Neihu Plant, and Zhongxing Plant. The types of the greenhouse gases are CO2, CH4, N2O, HFCs, PFCs, and SF62e (6.85%), primarily from equipment refrigerants and company vehicles. Scope 2 (Category 2) energy-related indirect greenhouse gas emissions, totaling 21,114.45 tCO2e (93.09%), primarily from use of purchased electricity. Category 4 other indirect greenhouse gas emissions, totaling 14.74 tCO2e (0.06%), primarily from waste disposal and transportation. Therefore, the Company’s greenhouse gas reduction strategy focuses on increasing power efficiency and reducing power consumption. The greenhouse gas emissions in 2024 increased slightly by 16.23 tCO2e compared to 2023, but the overall operating revenue increased by 18.38%, and the greenhouse gas emission intensity decreased by 14.17% compared to the base year 2022, achieving the goal of reducing greenhouse gas emission intensity by 5%. In 2024, six energy-saving programs were implemented, saving a total of 1,770.234 MWh of electricity (based on self-estimation), which is equivalent to a reduction of 874.5 metric tons of carbon dioxide equivalent.

Energy Management

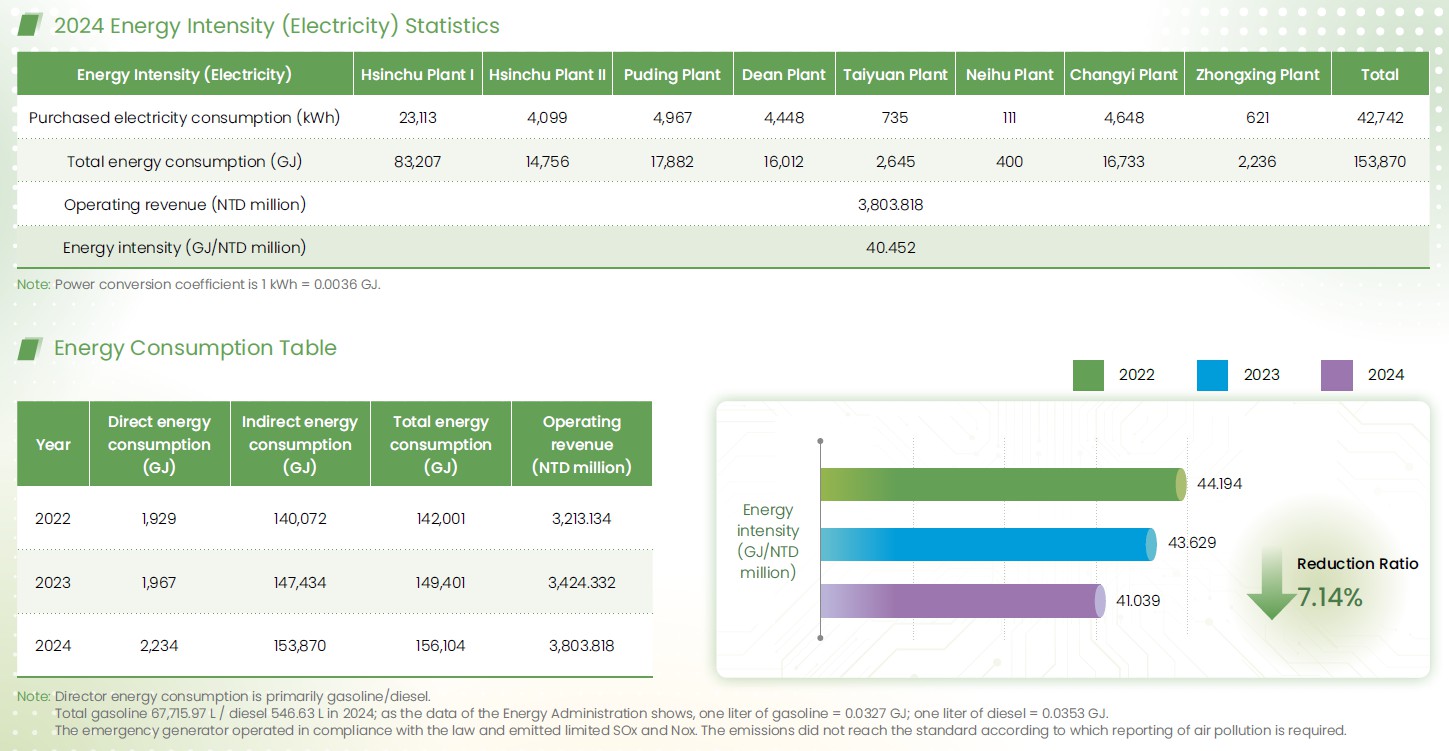

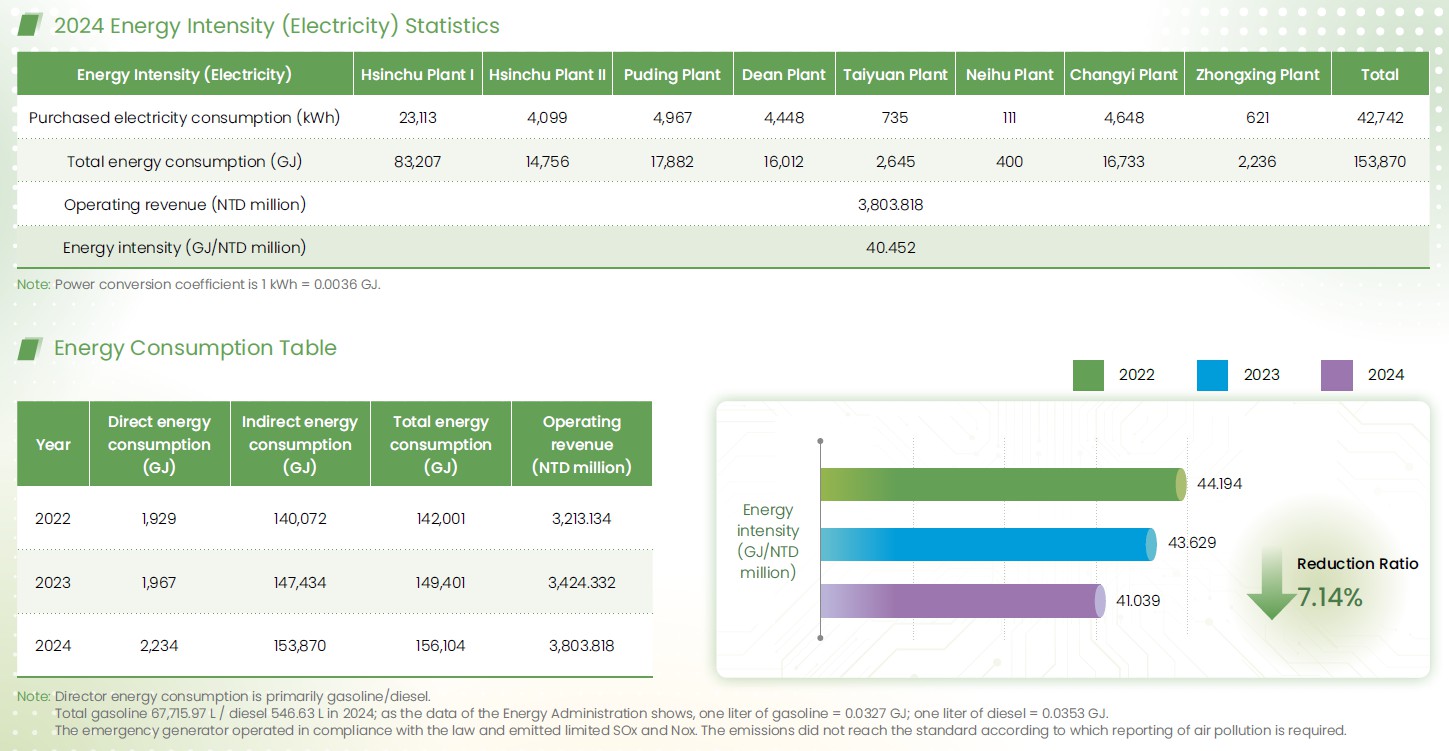

The energy sources that the Company uses include electricity and gasoline/diesel and exclude other energy types such as heating. Energy is sourced from government-owned power plants and gas stations, with electricity being the primary source. Gasoline is used for official vehicles, and diesel for generators. Construction of renewable energy facilities will begin in 2024, with activation expected in 2025. Electricity and energy consumption intensity are detailed in the table below.

Greenhouse Gas Management

Facing the challenge brought about by global climate change, we know very well that companies must reduce the GHG emissions generated from the operating process and thus mitigate the negative impact on the climate. In 2022, we were dedicated to promoting the awareness of green production and low carbon to facilitate premium ecological environment, fulfill our corporate social responsibilities, and put the corporate philosophy of sustainable operations into practice.

The Company established a greenhouse gas inventory management process in accordance with ISO 14064-1 and the greenhouse gas verification guidelines of the Ministry of Environment in 2021. In the same year, we conducted a self-inspection of greenhouse gas emissions at the Hsinchu Plant I. In 2022, the scope of the self-inspection was expanded to cover the entire plant. In 2023, the inventory results were verified by a third-party verification company, ensuring a complete understanding of the current greenhouse gas usage.

The GHG inventory of the Company is conducted with operational control as the boundary of the inventory organization. The plants participating in the inventory in 2024 are Hsinchu Plant I, Hsinchu Plant II, Puding Plant, Dean Plant, Taiyuan Plant, Changyi Plant, Neihu Plant, and Zhongxing Plant. The types of the greenhouse gases are CO2, CH4, N2O, HFCs, PFCs, and SF62e (6.85%), primarily from equipment refrigerants and company vehicles. Scope 2 (Category 2) energy-related indirect greenhouse gas emissions, totaling 21,114.45 tCO2e (93.09%), primarily from use of purchased electricity. Category 4 other indirect greenhouse gas emissions, totaling 14.74 tCO2e (0.06%), primarily from waste disposal and transportation. Therefore, the Company’s greenhouse gas reduction strategy focuses on increasing power efficiency and reducing power consumption. The greenhouse gas emissions in 2024 increased slightly by 16.23 tCO2e compared to 2023, but the overall operating revenue increased by 18.38%, and the greenhouse gas emission intensity decreased by 14.17% compared to the base year 2022, achieving the goal of reducing greenhouse gas emission intensity by 5%. In 2024, six energy-saving programs were implemented, saving a total of 1,770.234 MWh of electricity (based on self-estimation), which is equivalent to a reduction of 874.5 metric tons of carbon dioxide equivalent.

Energy Management

The energy sources that the Company uses include electricity and gasoline/diesel and exclude other energy types such as heating. Energy is sourced from government-owned power plants and gas stations, with electricity being the primary source. Gasoline is used for official vehicles, and diesel for generators. Construction of renewable energy facilities will begin in 2024, with activation expected in 2025. Electricity and energy consumption intensity are detailed in the table below.